LS-MARKPRO

CUSTOMIZABLE LASER PROCESSING MACHINE FOR HIGH ACCURACY APPLICATIONS

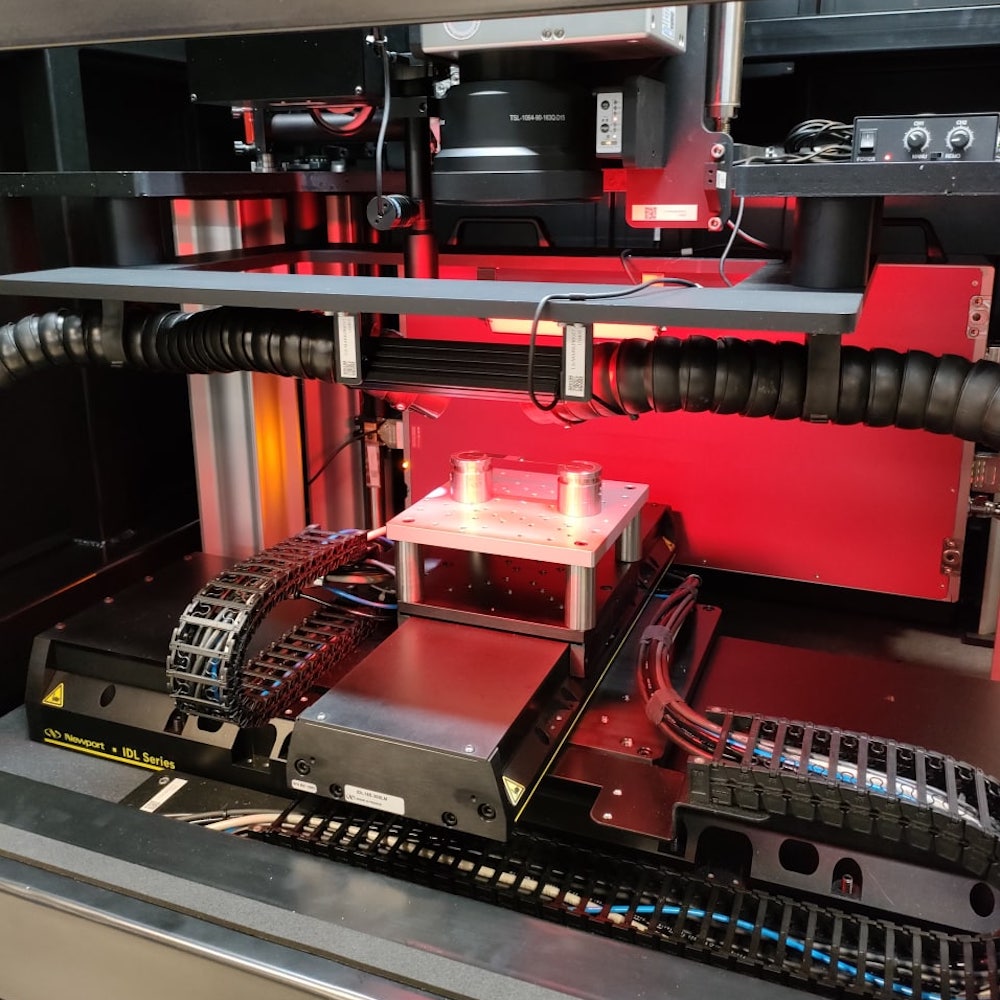

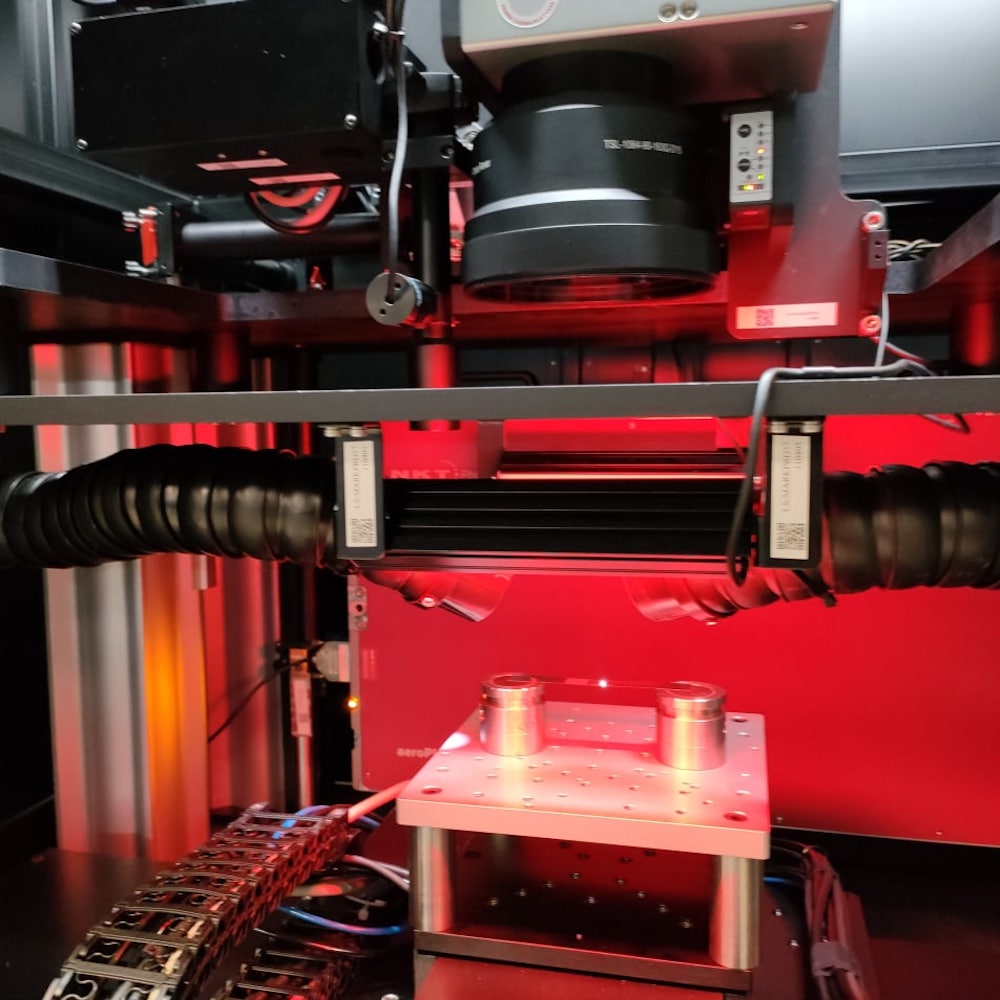

LS-MARKPRO is a versatile workstation designed for high demanding laser processing applications where nanometer resolutions and laser spot sizes down to 1 micron are required. The main heavy granite structure with pasive dampers and advanced solutions like close loop surface measurement for automatic focus correction, provides extremely high accuracy and stability even for complex trajectories. User friendly software with CAD GUI enviroment (codeless programming) ensure an efficient and fast process development.

Typical Specifications

| Working Area | Up to 500 x 300 x 150 mm |

| Resolution | 10 nm (XY), 0.3 μm (Z) |

| Repeatability | Down to ± 40 nm (XY); ± 0.5 μm (Z) |

| Accuracy | ± 2.5 μm (XY); ± 2.5 μm (Z) |

| Available Laser Sources | From UV to IR. Pulsed or CW |

| Substrate Holder | 250 x 200 mm Aluminium Vacuum Plate |

| Minimum Laser Spot Size | Typical from 1 μm |

| External Dimensions | 1400 x 1500 x 2200 mm (W x D x H) |

| Weight Aprox. | 1700 Kg without laser source |

| Control Unit | Workstation with dual 23″ monitor |

Features

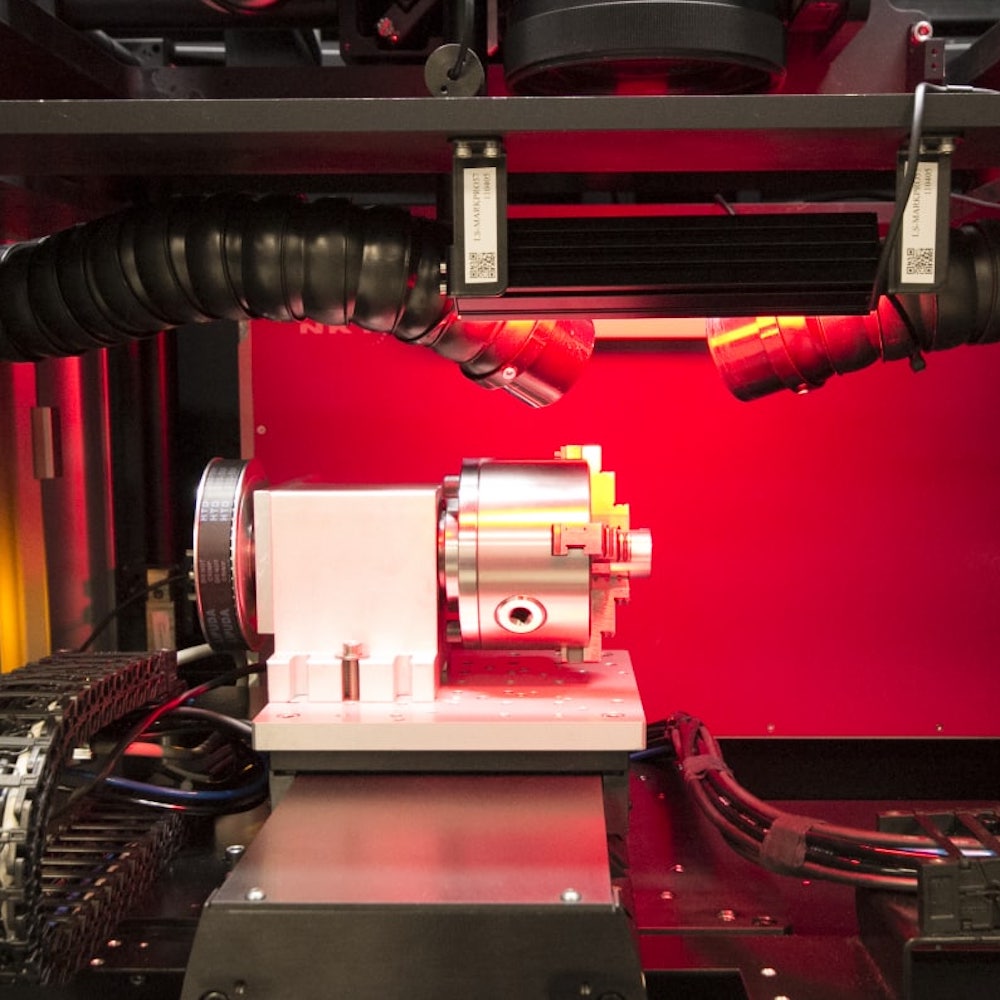

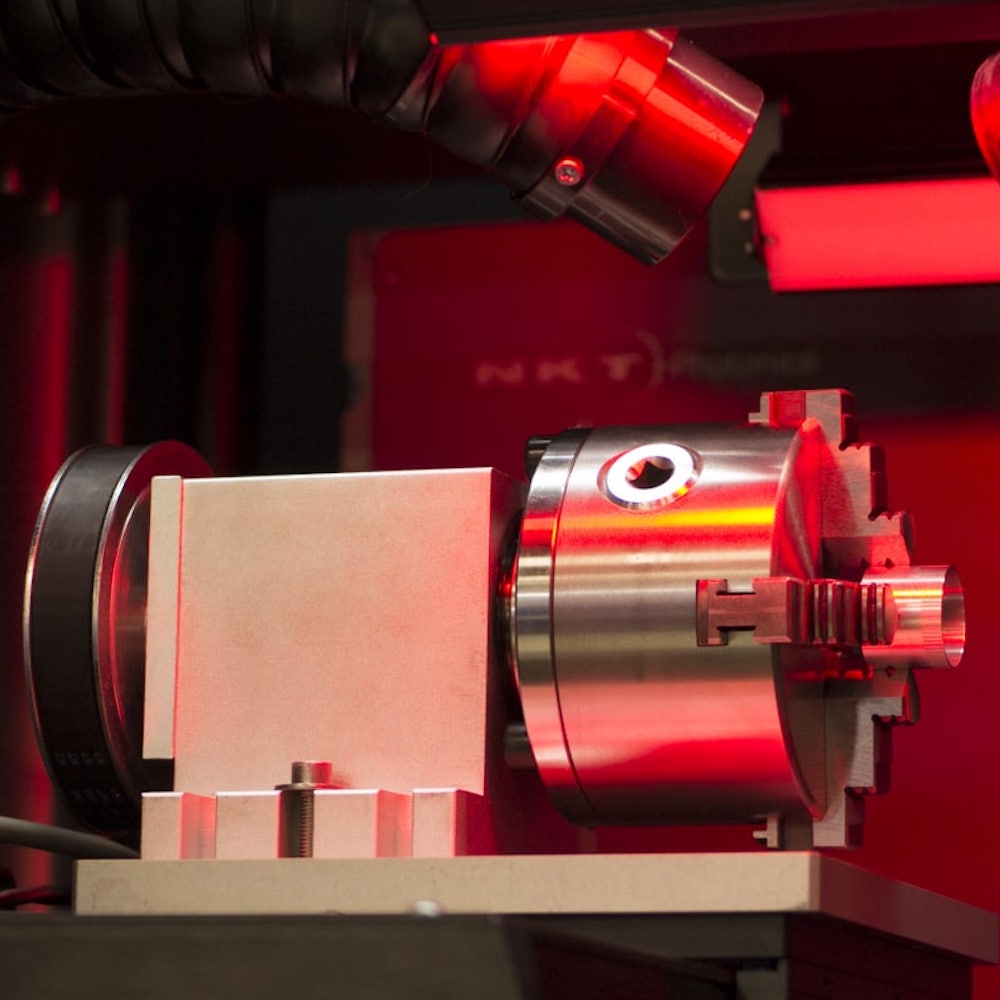

Fixed optic head with automatic objective´s change.

High Precision scanner head.

Automatic change from Fixed head to Scanner setup.

Co-lineal vision system with motorized optics.

Co-lineal surface measurement laser system with close-loop correction or 2D scanning option.

Automated camera calibration.

Automated feature camera recognition for precision aligment and rotation compensation.

Based on CAD GUI enviroment (Import DXF, DWG, DWT, ACIS… files).

Class 1 high end enclosure with automatic door and HMI panel.

Applications

Solar Cell Processing

Wafer scribing and dicing

Our Partners